29 Sep 2015: A pragmatic approach to improving the worker safety issues in Gurgaon-Manesar’s auto manufacturing sector

More than a thousand workers lose their hands and fingers in crush injuries in only Gurgaon-Manesar’s auto manufacturing sector. To help sustainably reduce such incidents, and to help the injured worker, a citizen initiative called ‘SafeInIndia’ had started a research on the subject to pursue pragmatic and win-win solutions to improve the working environment of these workers, while working collaboratively with the manufacturers.

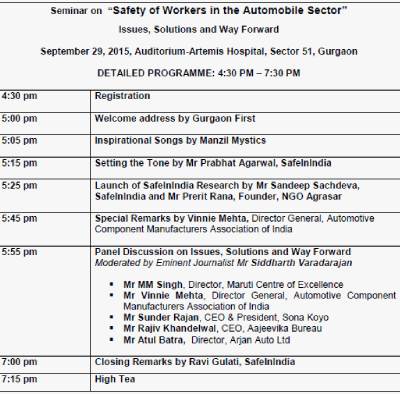

A panel discussion of senior industry and social sector executives was organized on September 29th, 2015, to discuss this subject at the Artemis Hospital Auditorium in Gurgaon. The event was attended by more than 200 delegates including manufacturers, workers, NGOs, and others.

Mr Prabhat Agarwal from SafeInIndia said “This complex problem doesn’t have only one guilty party. We are all involved. While we need to raise safety consciousness among both manufacturers and workers, the business needs to appreciate that the time and resources wasted in the aftermath of a single accident is an unrecognized huge cost.”

The Panel Discussion moderated by eminent journalist MrSiddharthVaradarajan, with speakers Mr MM Singh, Director, Maruti Centre of Excellence, Mr Vinnie Mehta, Director General, Automotive Component Manufacturers Association of India (www.acma.in), Mr Rajiv Khandelwal, CEO, Aajeevika Bureau (www.aajeevika.org), a leader in the area of improving the lives of migrant workers. Mr S Sandilya, Chairman Eicher Motors and ex-President, SIAM and Mr Atul Batra, Director, Arjan Auto Ltd, an auto component manufacturer.

Mr Vinnie Mehta was very complimentary about this initiative and talked about using the automotive industry’s hierarchical structure and how SafeInIndia will need to find ways to obtain support from the large car and motorcycle manufacturers, brands that people buy, to improve the safety culture inthousands of their supplying manufacturing units. For example, there could be a way to certify suppliers as safe.

Mr MM Singh, was passionate about the subject and admitted that he was himself shocked by the SafeInIndia research findings which points to the need for increasing the awareness among the manufacturers. He declared that MACE will improve the safety standards in its supply chain and will scale it up in near future.

Ajeevika’s CEO Founder, Mr Rajiv Khandelwal, argued for the need for public-private facilitation centres in migration-sensitive areas like Gurgaon/Manesar. These centres in his opinion could provide legal aid and support the workers at the time of any distress. According to him, big centres like manufacturers Gurgaon have the power to collectively pool their resources together and create these solutions for treatment, primary care, etc.

Mr Atul Batra, who was clearly moved by the case studies in the report, made a number of valuable practical suggestions. He felt strongly about locating ESI dispensaries in much more convenient locations for workers in individual industrial clusters which should be open 24/7 as many accidents happen in the night time when ESI hospitals do not have adequate medical staff.

MrSidharthVardarajan talked articulately about the increasing proportion of contractual workers, which in effect is nothing but a de facto hire and fire street level policy.He argued that if the industry wants more flexibility under labour laws to hire and fire depending on their business needs as is the case in many western countries, then the employers should also offer a suitable termination compensation to workers being fired just as it happens in those countries.

MrSandilya talked extensively about the need for the right attitude, about safety, in all aspects of life. He also advocated a joint ACMA-SIAM initiative to address this urgent issue, and suggested to SafeInIndia to put together another research report about the local and global best safety practices in the industry to help highlight how things can be done better.

Before the panel discussion, the SafeInIndia team presented their findings and recommendations from their research, conducted with Agrasar, an NGO. Some of the key findings were that of the 20 case studies, 80% had no training at all, 70% machines had no safety controls, 75% of injured workers were in their teens or in their 20s, 60% had no insurance cover promised to them under regulations, only 25% were permanent employees, 50% did not get support from employers after the accident, unions were of little support and in 90% of cases, the injuries led to a decline in their employability.

Mr. sandeep Sachdeva from SafeInIndia says, “Having had corporate careers, we understand that these issues tend to get left out in spite of the best intentions. Our job is to bring this critical issue of worker safety within the frame of industry to spark off collaborative win-win initiatives involving all stakeholders, including industry, workers, consumers and Govt”.